Why Stone wool rather than Glass wool //

Glass wool insulation products and stone wool insulation products have now become the main insulation materials. Not only Household needs, industrial needs but also use in ceiling tiles field.

Glass wool

Glass wool, also known as fibreglass is made from a mixture of natural and recycled glass (recycled bottles, car windscreens and window panes) which is melted at 1,450 °C, and is then spun quickly to create fibres

Stone wool

Stonewool is made from volcanic rock (dolomite, diabase and basalt), which is not a recycled material, but is an abundant resource. Stonewool gives a higher quality and performing product than Glass wool. They are melted at high temperatures (about 1,600°C), and then they are spun to form fibres. This wool is then packaged up into batts, rolls or slabs.

There has been much debate over the merits of stonewool compared to glasswool insulation. In the developing part of the world, there is also a lot of mis-information around the two materials. The simple answer is that the best material is dependent on the application and specific performance requirements.

![]()

HEAT LOSS

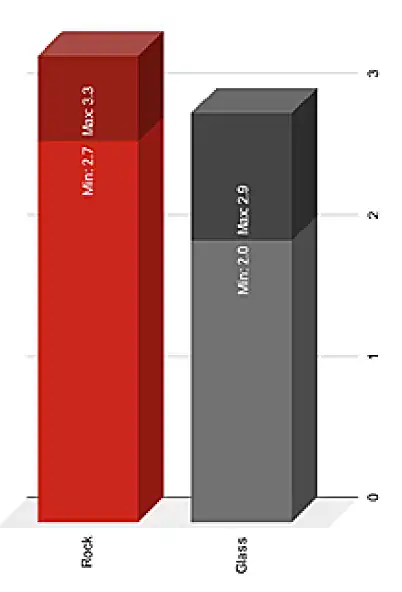

Rock mineral wool systems can attain R-values of around 3 to 3.3.

Glass mineral wool can achieve R-values of around 2.2 to 2.7, which is effective, but not as good as the values of rock mineral wool.

![]()

SOUND INSULATION

Rock mineral wool is a dense material, offering tremendous thermal and acoustic properties.

As a dense material, rock mineral wool provides exceptional protection against excess noise and as such, can be used to insulate properties against sound just as effectively

![]()

FIRE PERFORMANCE

Despite glass mineral wool and rock mineral wool both being cited as non – combustible, the actual fire resistance of each product varies.

Melting Temperatures //

According to several mineral wool insulation manufacturers, rock mineral wool has a melting temperature of over 1000°C. It has been well documented that glass mineral wool fibres have been tested to withstand temperatures of around 400°C.

| Melting Temperature | Combustibility | |

|---|---|---|

| STONE | Over 1000˚C | Euroclass A1 Non-Combustible |

| GLASS | Around 400˚C | Euroclass A1 Non-Combustible |

Many insulation solutions manufactured from glass mineral wool will meet the highest standards covered under BS EN 13501-1. However, it is important to check this as and when glass mineral wool insulation is chosen for a project, to ensure it does comply to this standard. Products made from glass mineral wool are also able to meet the best possible Euroclass ‘A1’ standard for reaction to fire classification.

Although glass mineral wool can be incorporated within a fire-stopping system, helping.

| Glasswool | Stonewool | |

| Material | Glass fiber | Stone or silica fiber |

| Cost | Low | Medium (roughly 10% higher) |

| Recycled content | 30 % | Up to 70% |

| Ease of installation | Hard | Easy |

| Fire resistance | Yes | Yes |

| Density (lbs./ft.3) | 6 | 8 |

| NRC | 0.6 – 0.9 | 0.8 – 1.0 |